Hydrogen Reformer System

A high temperature set of modular reactors that convert LPG (cooking gas) and water into Hydrogen through catalysis. The Hydrogen is used to generate electricity using a fuel cell. The system involved designing the reactors using special high temperature metals and seals, special manufacturing methods as well as specifying sensors and creating a full control/automation system. Many CFDs, thermodynamic and fluid mechanic calculations were completed as well as fatigue loading, compression/bolt loading, sealing calculations and specifications of sensors and pumps/fans. Further details and naming of client cannot be shared as it is strictly confidential.

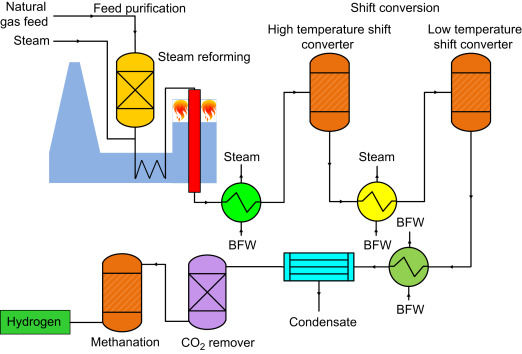

General System Diagram of Steam-Methane Hydrogen Reforming

Note that this is a general diagram

What I did

- Detailed Design

- Simulations, CFD, System Diagram

- Component and Sensor Specification and Procurement

- Thermodynamic, Fluid Mechanic, Compression and Fatigue Engineering

- Automation and Control (PLC)

- Frontend Web Development

- Assembly, Leak Testing, Welding and Commisioning

- Experimentation and Classification

- Design for Manufacture

- Reactor Improvement and Optimization

- Client Liasion and Project Management