Intelligent Grinding System

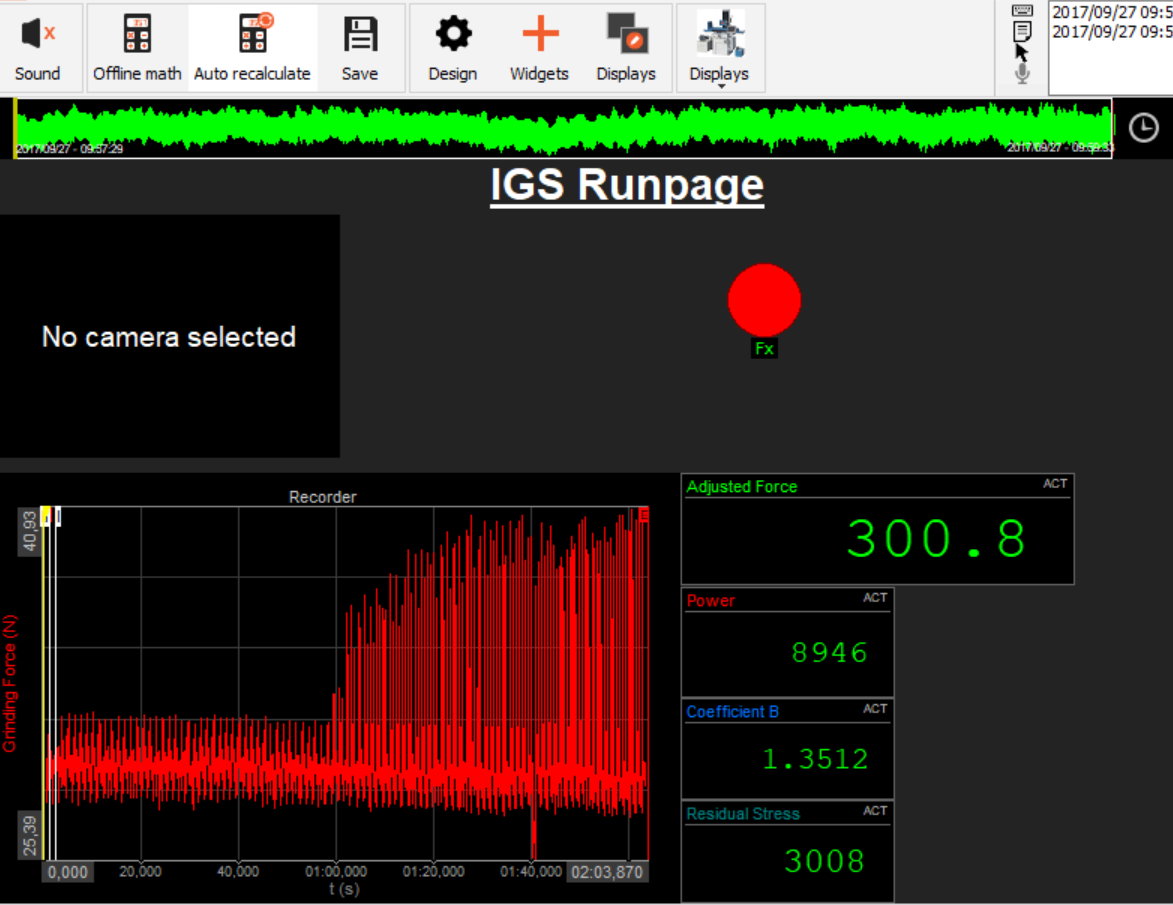

An application used in conjuction with real time data acquisition (DeweSoft DAQ) to optimize ground material parameters (namely minimization of residual stress and workpiece burn) and grinding process parameters (namely minimization of wheel wear and process time).

Results Page

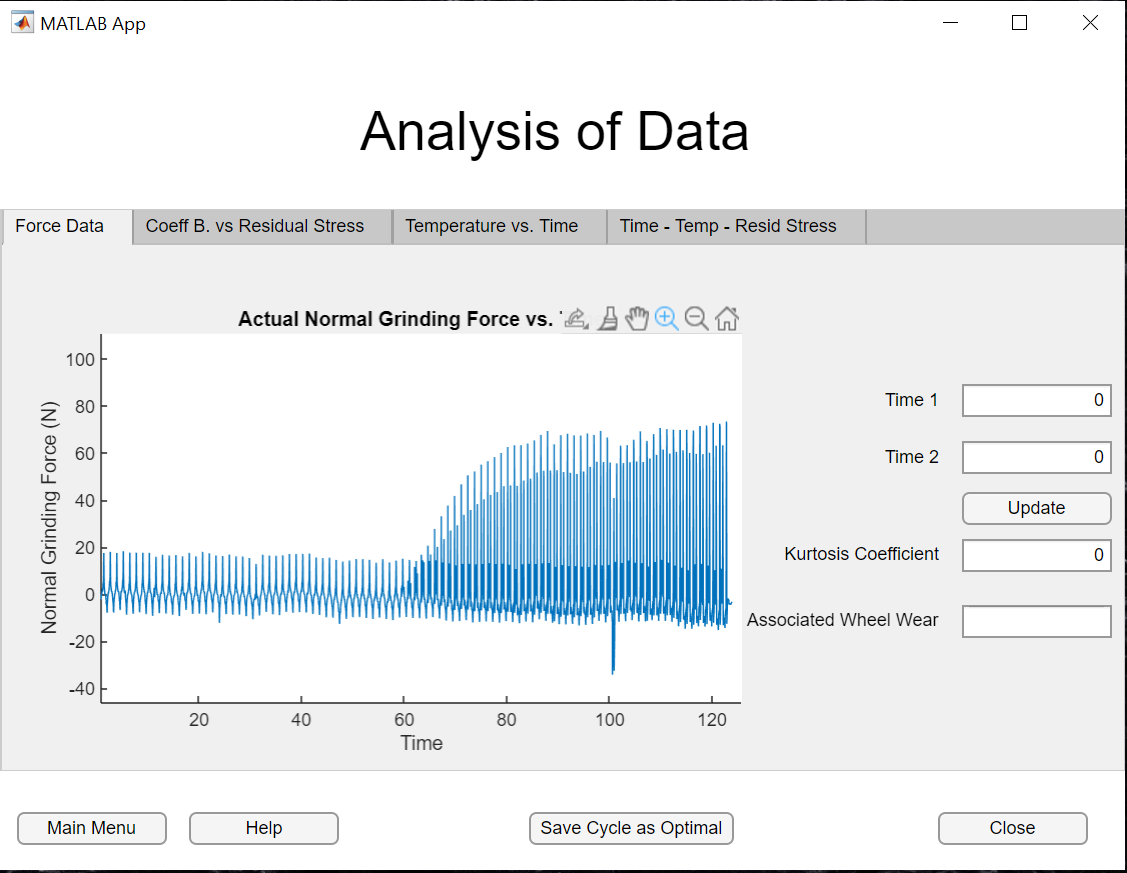

The developed MATLAB application combined with a seperately developed MATLAB model allowed for the analysis of data acquired from a dynamometer and was transferred to another student who implemented it in real time. The model was based on how simple measurements (force, temperature) could be converted to meaningful data (Residual Stress, Burn Information, Wheel Wear).

What I did

- Research

- Process Design and Modelling

- MATLAB Application Development

- MATLAB Modelling

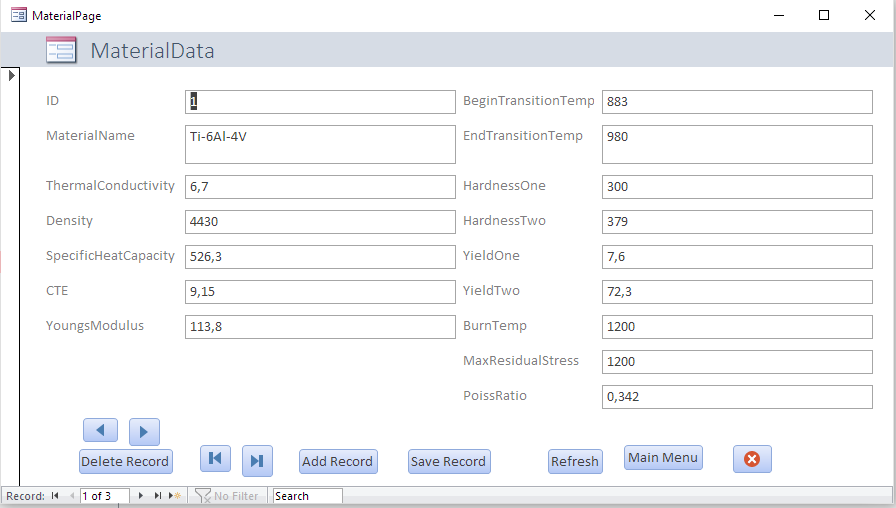

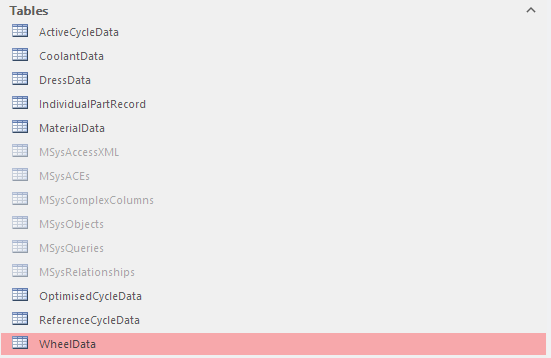

- SQL Database Design and Query (Microsoft Access)

- Validation with Data Sets

- Report Write Up