Flexolap

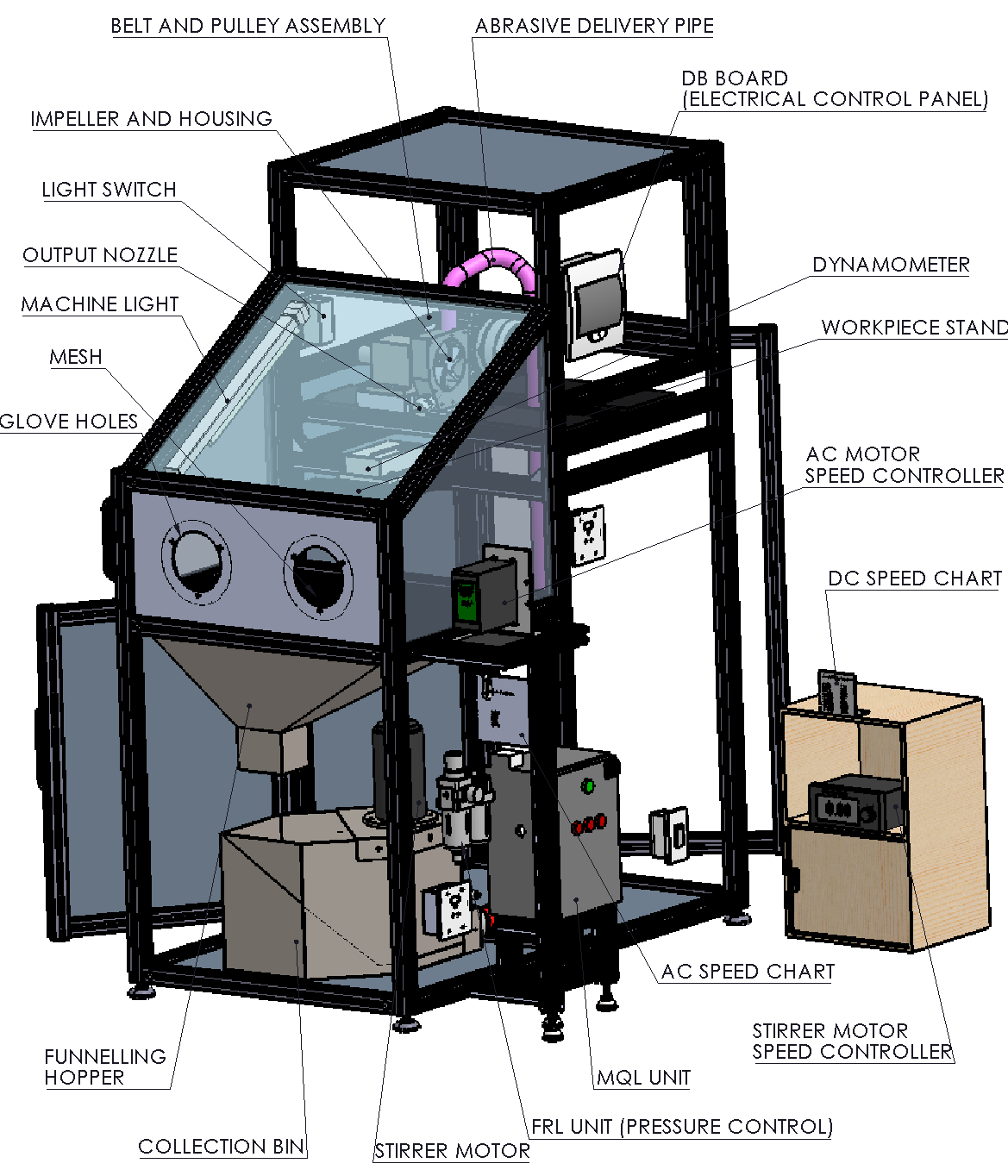

A fully functional advanced manufacturing machine for the flexible abrasive assisted mechanical polishing of components.

Designed, modelled and built from the ground up, succesful results in polishing Ti-6Al-4V components down to 0.1 microns were acheived.

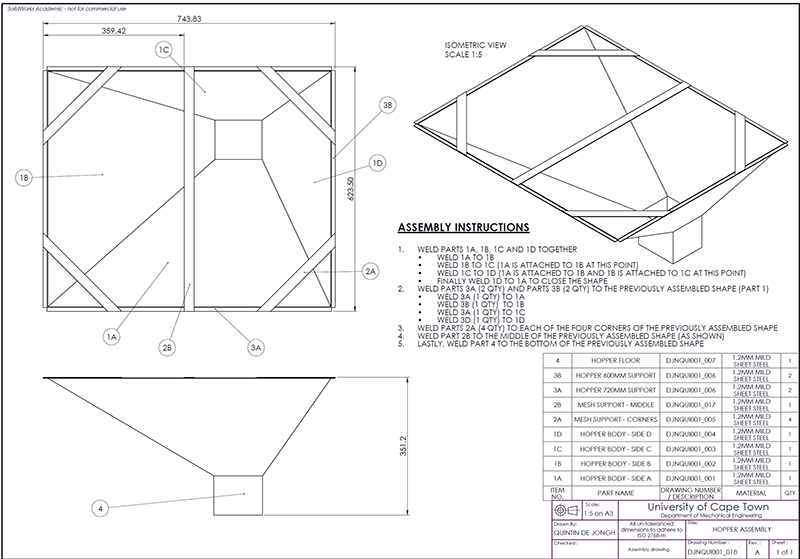

Final Design Drawing

Aluminium T-Slot extrusions, associated extrusion accesories (door handles, connection joints e.t.c) and aluminium plated polyethylene sheets (I-Bond ACM) were used to make the sealed external frame. Pneumatic design and electrical design was incoporated to provide a suction system for abrasives and a controllable rotation for the discharge of abrasives. Results were verified using a profilometer and SEM.

What I did

- Process and Machine Element Design

- CAD/Solidworks

- Electric, Pneumatic and Mechanical Design and Assembly

- MATLAB Modelling

- Research

- Experimentation and Validation

- Sourcing and Acquiring Components

- Dissertation Write Up